As a process engineer with over two decades of experience implementing fiber optic sensing solutions across various industries, I’ve witnessed firsthand how this technology has transformed the way we monitor and manage critical infrastructure. The evolution of fiber optic sensing has revolutionised our ability to detect, measure, and respond to environmental changes with unprecedented accuracy and reliability.

Understanding Fiber Optic Sensing: The Basics

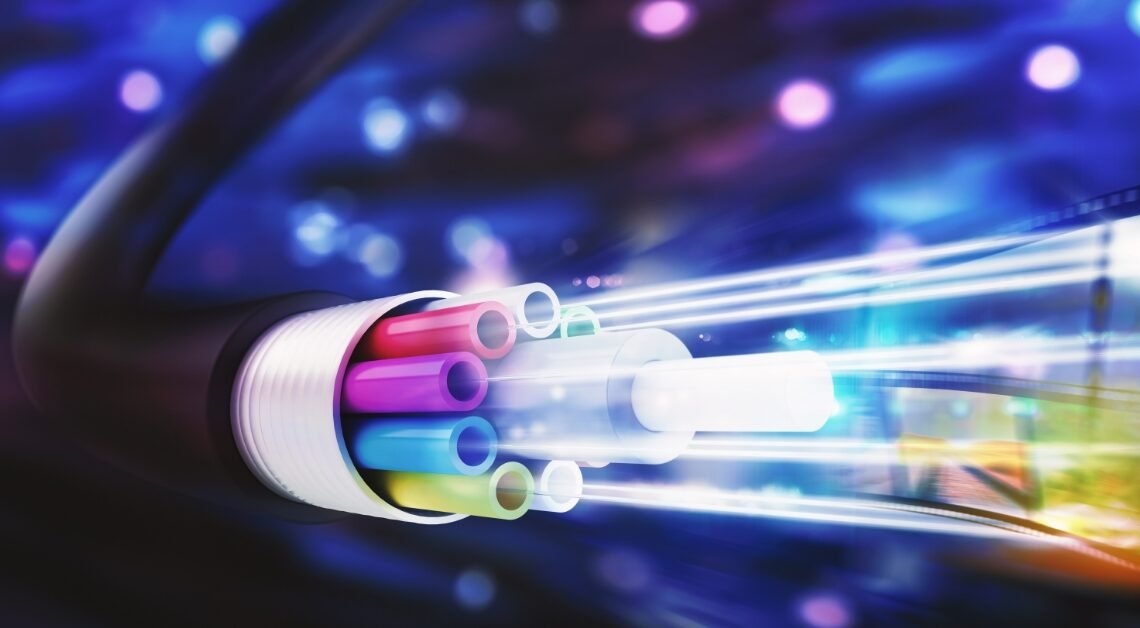

At its core, fiber optic sensing technology utilises light patterns within optical fibers to detect changes in temperature, strain, pressure, and various other parameters. Unlike traditional sensors, these systems can monitor thousands of points simultaneously along a single fiber, creating a continuous sensing network that spans kilometres.

How Fiber Optic Sensing Works

The science behind this technology is fascinating:

Light Propagation

– Laser pulses travel through the optical fiber

– Changes in the surrounding environment affect light properties

– These variations are measured and analysed in real-time

Distributed Sensing

– Each section of the fiber acts as a sensor

– Continuous monitoring along the entire length

– Precise location identification of events

Core Technologies in Fiber Optic Sensing

1. Distributed Temperature Sensing (DTS)

– Temperature monitoring along the entire fiber length

– Resolution down to 0.1°C

– Measurement distances up to 30km

2. Distributed Acoustic Sensing (DAS)

– Detection of vibrations and acoustic signals

– Real-time monitoring of dynamic events

– Applications in security and asset protection

3. Distributed Strain Sensing (DSS)

– Measurement of material deformation

– Structural health monitoring

– Early warning of potential failures

Industry Applications

The versatility of fiber optic sensing solutions spans numerous sectors:

1. Oil and Gas

– Pipeline leak detection

– Well monitoring

– Flow assurance

– Reservoir management

2. Power Infrastructure

– Cable temperature monitoring

– Transformer health assessment

– Underground cable protection

– Overhead line monitoring

3. Civil Infrastructure

– Bridge and tunnel monitoring

– Railway track surveillance

– Building structural health

– Dam safety monitoring

Key Benefits of Fiber Optic Sensing

1. Operational Advantages

– Real-time continuous monitoring

– No electrical components at sensing points

– Immune to electromagnetic interference

– Long-distance capability without signal degradation

2. Cost Benefits

– Reduced maintenance requirements

– Lower installation costs compared to multiple point sensors

– Extended asset lifecycle through early problem detection

– Minimised downtime through predictive maintenance

3. Safety Improvements

– Early warning of potential failures

– Remote monitoring capabilities

– Intrinsically safe operation

– Comprehensive coverage without blind spots

Implementation Considerations

When deploying fiber optic sensing systems, consider:

1. System Design

– Environmental conditions

– Required measurement parameters

– Spatial resolution needs

– Data processing requirements

2. Installation Requirements

– Cable routing and protection

– Integration with existing systems

– Power supply considerations

– Data communication infrastructure

Emerging Trends and Innovations

The field continues to evolve with:

Advanced Analytics

– Machine learning integration

– Pattern recognition

– Predictive maintenance algorithms

– Automated response systems

Enhanced Capabilities

– Higher spatial resolution

– Extended measurement range

– Multi-parameter sensing

– Improved signal processing

Best Practices for Deployment

1. Planning Phase

– Define clear objectives

– Identify critical monitoring points

– Assess environmental conditions

– Plan for future expansion

2. Implementation

– Use qualified installers

– Follow industry standards

– Document installation details

– Conduct thorough testing

3. Operation

– Regular system validation

– Data backup procedures

– Staff training

– Maintenance scheduling

Common Challenges and Solutions

1. Environmental Factors

– Temperature extremes

– Mechanical stress

– Chemical exposure

– Installation constraints

2. Technical Considerations

– Signal attenuation

– Data processing requirements

– System calibration

– Integration with legacy systems

Future Perspectives

The future of fiber optic sensing solutions looks promising with:

* Integration with IoT platforms

* Enhanced artificial intelligence capabilities

* Improved sensor designs

* Extended application areas

* Greater cost-effectiveness

Maintaining System Performance

To ensure optimal operation:

1. Regular Calibration

– System accuracy verification

– Parameter adjustment

– Performance documentation

– Compliance checking

2. Preventive Maintenance

– Cable inspection

– Connection verification

– Software updates

– System optimization

As we continue to push the boundaries of what’s possible with fiber optic sensing solutions, companies like Power Technologies are leading the way in developing and implementing these advanced monitoring systems. Whether you’re managing critical infrastructure, optimising industrial processes, or ensuring public safety, fiber optic sensing technology offers unparalleled capabilities for comprehensive, reliable, and cost-effective monitoring solutions.

The integration of these systems represents not just an upgrade to existing monitoring capabilities, but a fundamental shift in how we approach asset management and safety assurance. With continuous advancements in fiber optic sensing technology, we’re entering an era of unprecedented control and insight into our critical infrastructure and industrial processes.