When we talk about electronic designs for many, it is a piece of equipment or an electrical circuit appliance. Nowadays, many of these appliances are domestic, like washing machines or a refrigerator. However, these in-depth teams require a very complex process that few can understand.

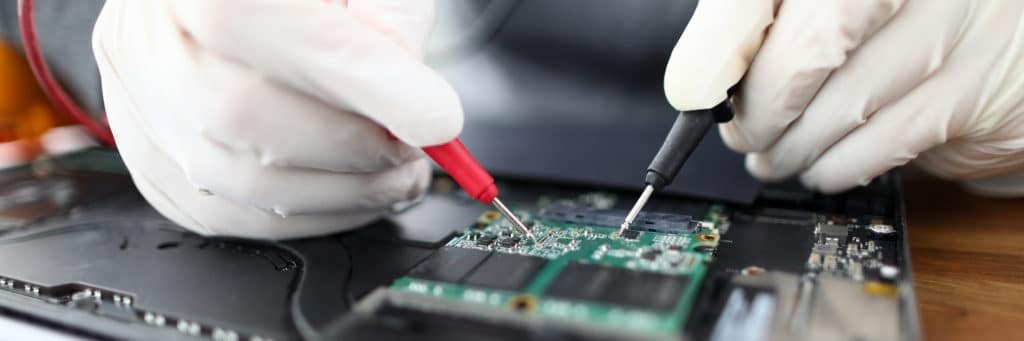

To handle terms, we will talk about the PCB, which is the acronym in English for Printed Circuit Board. Here begins our electronic design, a card, or board with a circuit, components, and a large amount of current and information that passes through it.

What it is, and the process of electronic PBC assembly?

For some experts, the PCB is the place of accommodation for the electrical components of a circuit. This type of piece is the green base that you may have found when opening a computer or mobile.

It is composed of electrical routes and combined with electrical components; they facilitate the current passage. This printed circuit board has the following built-in features:

– Connectors

– Displays

– LEDs

– Processors

At the top of the board, these components are unique in ways that make driving easier. These passages are found on the plate. It is what gives it the name of the printed circuit board.

How does it work?

A PCB board is designed under a concept of storage and support of electrical components. The pieces that facilitate connectivity between elements rest there for a device to function correctly.

Currently, PCBs have evolved to the point of performing new functions. Specialists in the field explain that technological development has focused on faster products and smaller equipment.

What can modern PCBs do?

The technological innovation era is advancing by leaps and bounds and encompasses such attractive sectors as electronic PCB assembly. Thanks to this, printed circuit boards are required to meet specific characteristics, such as:

Thermal PCB Models

The temperature generated in an electronic device must be regulated directly from the plate. Both internally and externally, high temperatures can damage the equipment. If the PCB has integral solutions to control these values, it is good design. In addition to this, the equipment’s lifetime is increased, making it useful and functional for longer.

Efficient and noise-free hobs

In addition to regulating temperature, PCBs must be fast and tailored to the speed needs of users. It cannot go very fast or very slow, just at the right speed. By being in tune, it ultimately reduces the noise generated by old plates.

They are made faster

The manufacturing time of a PCB has been reduced thanks to the previous design processes considerably. It does not decrease quality because it combines excellent tools.

They are more advanced and smaller

The fight for the leadership in mobile equipment sales depends on functional features, but smaller. For this, a complex PCB but capable of entering these tiny spaces is of utmost importance for customers.

Leading technology solutions facilitate each of these functions. HELTRONICS, for example, helps you have a more dynamic PCB and integrated it into any other tool. How much we combine, we join forces to finish our projects with quality and in good time. To know more, click here for electronic pcb assembly.

The challenges of electronic engineering

Currently, it seeks to meet critical challenges to improve and continue innovating with PCBs. One of these is knowing how to get around the number of components an electronic board should have.

Thus, it is considered the most significant obstacle when designing them, coupled with the manufacturing time, the budget, and incredible benefits. The technology industry is one of the largest customers in terms of PCB. Their equipment requires circuits that facilitate communication between components and their proper operation.

Therefore, this has made electronic PCB assembly become an integral challenge within device engineering. Professionals are obliged to improve their processes because the future will depend on these pieces. Everything will have printed circuit boards because there is electronic, mechanical, digital, and technological integration in the coming years.